| Sign In | Join Free | My rc363.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My rc363.com |

|

Brand Name : CPA

Model Number : CPA-TM

Certification : CE,ISO

Place of Origin : Jiangsu ,China

MOQ : 1 SET

Price : Negotiate

Payment Terms : Western Union, L/C, T/T

Supply Ability : 160 sets per year

Delivery Time : 35-80 working days

Packaging Details : Wrapped Film \Wooden box\Carton box

Processing Types : Tomato Paste

Weight : Customized

Washing Type : CIP Clean In Place

After Sales Service : Engineer Goes To Production Site

Evaporate Type : Continuous Vacuum Evaporate

Processing Steps : Washing, Sorting, Crushing, Preheating, Pulping, Concentrating, Sterilizing, Aseptic Filling or Small Package like tin can \bottle\sachet

Filling Accuracy : ±1%

Material : Stainless Steel 304

Power : 50-550kw

Cooling Method : Water Cooling

Type : Tomato Paste Production Line

Heating Resource : Steam,electricity,gas

Control System : PLC SIEMENS 1200 Automatic Control

Filling System : Automatic

Processing Capacity : 1-50T/H Tomato Input

Warranty : 2 Years

Condition : New

Application : Concentrated Tomato Paste Plant

Keywords : Easy Operate High Productivity

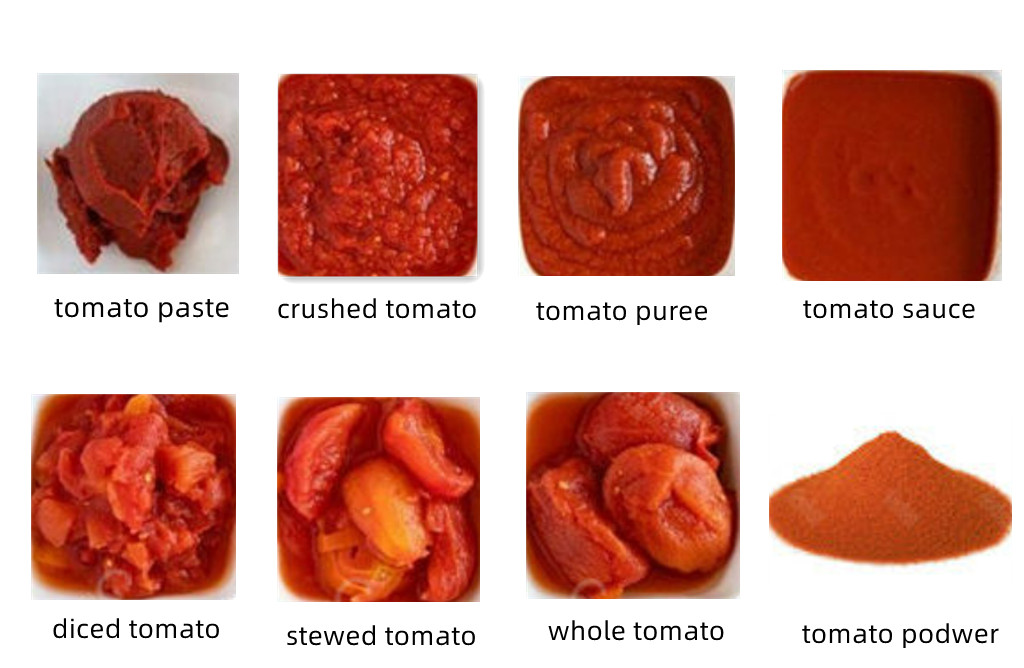

The tomato processing line can produce different kinds of final products from fresh tomatoes. Popular products such as tomato paste, tomato ketchup and canned tomato, tomato juice.

The main product is tomato paste ,the typical tomato paste production line mainly includes: fresh tomato receiving system, washing system, sorting system, crushing system, pulping refining system, filtration system, concentration system, sterilization system, aseptic filling system. Then we can get the ketchup in the aseptic bag in the barrel.

Tomato paste in barrels aseptic bags can further produce ketchup, sauces, juices, and can be filled in small bags, stand-up bags, metal cans, PP containers, bottles, gable tops, etc.

Fresh fruit -receiving-elevating-washing-sorting-crushing-pre heating-pulping and refining-vacuum concentration-aseptic filling -tomato paste in aseptic bag

tomato paste in aseptic bag-blending-sterilization-filling -post pasterurizer -drying -tomato ketchup in small packages such as tin cansmall pouch glass bottlepet bottle

tomato pastecrushed tomatotomato pureetomato saucediced tomato stewed tomatotomato powder

| 1 | Product Name | Tomato Paste Production Line |

| 2 | Processing capacity | 1-50T/H |

| 3 | Type | Turn-key project |

| 4 | Final product | Tomato paste |

| 5 | Product brix | 28-30/36-38 |

| 6 | Warranty | 1 year |

| 7 | Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| 8 | Service | Life-long service |

| 9 | Help | Package design and purchasing |

Aseptic bag in drumstin can small pouch glass bottleplastic bottle

Receiving and Conveyor Pot:It acts as a collection piont where tomato are deposited ,ofter used for a big line

Elevator:are vertical transportation devices that are commonly used to move and transfer tomato from conveying pot and sorter

Sorter :manual sort and classify ,separate

Crusher :A tomato crusher is a specialized piece of equipment used in the processing of tomatoes ,to crush tomato into small pieces

Preheater:Heating the tomatoes helps to sften the skins and flesh ,making them easier to crush ,juice ,or peel

concentration:tomato concentration refers to the process of reducing the water content in tomato juice ,pulp ,or puree to create a more concentrated tomato product ,we used continuous concentrated machine to keep tomato paste a good quality

Tube in tube sterilizer:A tube in tube sterilizer ,also known as a tubular heat exchanger ,is a specialized piece of equipment used in food and beverage processing to sterilizer liquid products.

Aseptic filler :The main purpose of an aseptic filler is to package products like juices, dairy, and other liquids in a way that prevents any microbial contamination, ensuring a long shelf life without the need for refrigeration.

|

|

Automatic Tomato Paste Manufacturing Plant Auto Tomatoes Paste Producing Machine Factory Machines Equipment China Price Images |